Whenever I have a chance, I still enjoy just watching the chips fly. Or, as with tapping, the chips spiraling out of a hole in a perfect helix.

This is a tap from one of my favorite jobs. It's an OSG 3/8-16 with thru coolant.

As mentioned in an earlier post, my first job in the trade was running a large Mazak vertical mill. My favorite job used all of its power and versatility.

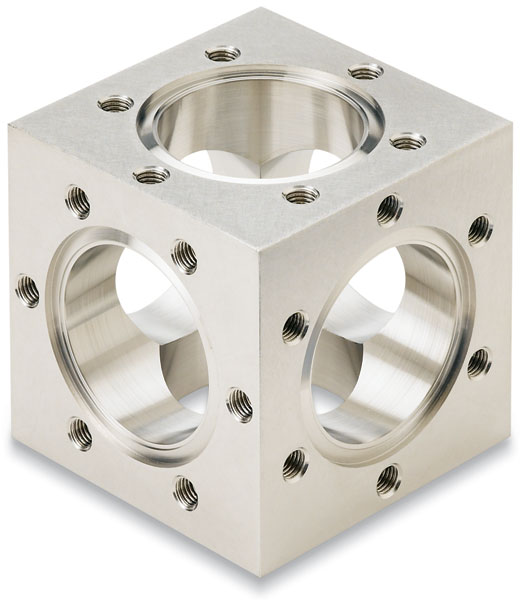

This is a 304 SS 6-way cube from the Kurt J Lesker Co. They are used to connect vacuum tubes and for mounting equipment. From memory, this one measures 6" on a side.

The blanks for the 10" cubes would come in close to 11", with a six inch core taken out of one axis. I had to use a jib boom and winch to get one up onto the table. Once clamped in a vise I would mill a rough pass around the top of the profile, then face and finish the bore to 8" diameter and about 4 inches deep. The steps inside the counter-bores are knife edges, when another component is bolted on a copper seal is placed in between and the knife edges dig into the soft copper forming a positive seal. Once the inside was done, the bolt pattern is drilled. The above cube has six 5/16-24 holes tapped about .625 deep. The 10" needed 12 3/8-16 per face. We had some trouble with with the OSG drills at first, but once we realized that they ran at 45 sfm we were off. Now comes the tapping. Using the Mazak's thru coolant and rigid tapping cycle, I would tap these holes on 10-12 parts without fear of breakage. Can't remember the spindle speed but probably 60 to 100 rpm.

Next I would bolt the finished face to a 4th axis and repeat the process for each face, but adding an insert drill and 1 1/4" hogging end mills to open up the bores. The facing of the part would be done with 6" shell mills (Iscar?) with round inserts for roughing and octogonal for finishing. Full engagement, .120 depth of cut, no coolant. more than a decade later I still have some of the chips in my battered Kennedy toolbox.

|

| Notice the golden color, hot enough to carry away the heat but not the blue of burning. |

Back to the vise, repeat for final face. Be careful to put it in the correct orientation, notice how the holes have to be offset or they will interfere with each other.

When done, the cube weighs 15 to 20 pounds about a quarter of the blanks weight(if memory serves).

Anyone else have a tool they just can't part with? Or am I just being overly sentimental?

Ps. I finally wised up and enabled comments!

This comment has been removed by a blog administrator.

ReplyDeleteConsidering the immense popularity enjoyed by robinets vente at reduced rates, it's not astonishing that every main brands are leaving no robinets cascade unturned inside as being a piece of the gravy train. The robinetterie baignoire selection of designs plus styles has ensured that the radioactive stocks of these elegant, distinctive plus affordable robinets LED fly off the shelves inside shops with amazing briskness. Pot filler or individual hole faucets, pull-down or pre wash, pull-out or individual lever mitigeur douche, two-handle or wall-mount faucets for your kitchen, the options are simply staggering.

ReplyDeleteThis is my first time i visit here and I found so many interesting stuff in your blog especially it's discussion, thank you.

ReplyDeleteKitchen Taps

Superbly written article, if only all bloggers offered the same content as you, the internet would be a far better place..

ReplyDeleteBathtub Taps